Synthesis and Characterization of a Biodegradable Polymer

Introduction

Poly(alkylene oxide) polymers are biodegradable

and have many important applications, from chemical and biological synthesis

to electrolytes for solid state batteries. The polymer may be synthesized

from poly(ethylene glycol) (PEG), which is inexpensive and commercially available

in average molecular weights from 200 to 10,000. When PEG undergoes a Williamson

Condensation reaction under nitrogen and in the presence of KOH in dichloromethane,

an unbranched poly(ethylene oxide)is formed (Scheme 1).1,2 For

example, PEG400 results in a polymer with average molecular weight of 50,000.

After synthesis, this polymer may be characterized by NMR, thin film IR, mechanical

load testing, impedance, DSC and SEC. Its mechanical properties may also be

compared to other common polymers.

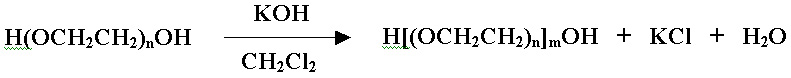

Scheme 1. Polymerization

of polyethylene glycol, for example PEG400, where

n = 8 to 9.

Synthesis and Characterization

Lab #1

CAUTION: KOH IS CORROSIVE, WEAR GLOVES AT ALL

TIMES.

At beginning of the lab, place the glassware to be used in this

lab period in the gray oven. The reaction is carried out in the nitrogen-purged

glovebox. Finely grind 14.0 g of KOH to a powder in a mortar and pestle. Only

when you are ready, remove a 100 ml flask from the oven (use gloves or paper

towels), and weigh by difference 12.5 g of KOH into the flask. Add a stir bar

to the flask and immediately place into the glove box, along with a teflon spatula

and two 25 ml graduated cylinders from the gray oven. Immediately close and

purge the antechamber at least twice, as per the posted instructions. From inside

the box, retrieve the items, close the antechamber, then purge the box at least

twice.

Place a small cold bath (dry ice in acetone, or ice, introduced into the box

via a sealed jar) on the magnetic stir plate. Add 12.5 ml of anhydrous

dichloromethane (reagent already in the glove box) to the beaker with KOH. Mix

the contents manually with the spatula until homogenous, then clamp in place

in the ice bath above the stir plate and begin the stirrer. Slowly add 12.5

ml of the viscous poly(ethylene glycol) 400 (reagent also already in the glove

box). The reaction is initially exothermic. When the addition of PEG400 is complete,

the ice bath is removed from the glove box. The reaction mixture is stirred

until it becomes viscous and the stirrer has difficulty stirring (approximately

30 to 60 minutes). An additional 12.5 ml CH2Cl2 is then

added. The flask is covered with parafilm, labeled and kept in the glove box

with positive nitrogen pressure until the next lab period.

Lab #2

The excess CH2Cl2 is removed using a vacuum

line equipped with a nitrogen-cooled trap or a rotovap. Alternatively, heat

gently (less than 60°C) in a sand bath in the glove box until dry. The flask

is removed from the glove box and the polymer removed from the flask (cleanup

of the flask is easy since the polymer is water soluble). Cut the polymer into

small pieces and dissolve in ~ 70 ml distilled water in a clean beaker. Mix

the slurry with a stir plate. The solution is poured into four dialysis tubes

(MW cutoff = 5000 Daltons). The dialysis tubing is cut to approximately the

height of the pipette washer, and one end is tied off. Fill the dialysis tubing

approximately two-thirds with the aqueous polymer solution. A small funnel may

be used for filling. The tubing is kept wet while filling. The ends of the tubing

are folded over and secured with the orange clips that can be labeled. When

the tubes are clipped, they are placed in a pipet washer with constant distilled

water exchange until the next lab period.

Lab #3

Examine the high molecular weight polymer in the dialysis tubing.

If there are particles in the aqueous solution, gravity filter through glass

wool into a 125 ml Erlenmeyer flask equipped with a magnetic stir bar and gas

inlet, weighing the empty flask, bar and inlet apparatus first. Distill away

excess water at reduced pressure (again using a vacuum line or rotovap) and

dry by heating under vacuum (vacuum line or use a hot water bath--do not boil--and

pull vacuum with an aspirator) for at least two hours. It may take longer to

remove all of the water. Place the apparatus in the glove box and weigh by difference

the mass of product. The glass transition temperature of this polymer is -60°C

and its melting temperature is 10°C.

Lab #4 and 5

Place a small amount of the polymer in a vial and remove from

the glove box. Dissolve a small amount of polymer in deuterated chloroform and

run the 1H NMR spectrum in S2-G14. You need to coordinate with the

NMR specialist, Dr. Schulte one lab period in advance so that he can run your

NMR sample. Also obtain the IR spectrum by dissolving a small amount of the

polymer in acetonitrile in the fumehood and make a thin film on shrink wrap

by dropping the polymer solution onto the wrap and allowing to air-dry. Alternatively,

use NaCl plates with either the pure polymer or Nujol mull.

Finally, evaluate the strength of the polymer on the mechanical

load testing equipment. Make a solid piece of the polymer be heating on a hot

plate into a mold, or heat the polymer into one piece and cut into shape with

an industrial blade. Your instructor will mount the sample on the Instron equipment

and collect the data. Collect the data for several other polymers that are also

supplied.

Lab Report

Based upon the integration in your 1H NMR, calculate

the ratio of methoxy to ethoxy peaks in your co-block polymer. How does this

NMR compare with the NMR of PEG400? Note: there are no methoxy peaks in PEG400,

while there are terminal hydroxymethylene (CH2OH) peaks in both PEG400

and the co-block polymer. Do not compare integrations between spectra, since

they are relative to the specific sample only.

Assign the significant peaks in your IR to specific organic

functionalities, paying particular attention to the peaks from 1500 to 600 cm-1.

How does the experimental IR compare with the reference IR?2

Compare the polymer strength with known polymers, both like

and unlike the polymer you synthesized.

Acknowledgments

The mechanical testing portion of this experiment was supported

by a grant from the NSF-DUE-CCLI-A&I (0310454, PI: Professor Stevens).

References

1. Lemmon, J. P.; Kohnert, R. L.; Lerner, M. M. Macromolecules

1993, 26, 2767- 2770.

2. Lemmon, J. P.; Lerner, M. M. Macromolecules 1992,

25, 2907-2909.

![]()